Semi-Automatic vs. Automatic Carton Sealers: Which One is Right For You?

Your produce packaging business is growing, and you need to add or replace carton sealers to keep up with demand. But how do you know which one is right for your business?

This article will give you the information you need to make an informed decision based on your unique warehouse needs.

What is a carton sealer?

Carton sealers are a vital part of the packaging process. Carton sealers are machines that place adhesive tape on the top & bottom of the box simultaneously.

They're often found in warehouses and distribution centers, where they're used to package products for shipping or for storage. The machine ensures that everything is properly packed so that manufacturers, wholesalers, and retailers can ship goods quickly without worrying about them getting damaged on their way to customers' homes or businesses.

This machine is designed to ensure that the product is protected from damage during transport by using compressed air to create a tight seal around the edges of the box. This prevents moisture from getting inside during transit, which can cause damage over time if it's not properly protected. It also helps keep out dust particles that could get into the product during transport, which could cause contamination problems later on when it gets opened at its final destination.

Advantages of Automatic Carton Sealers over Manual Carton Sealing:

- Increased production

- Reduces labor costs and increases efficiency

- Reduces waste (a semi-automatic or automatic carton sealer only requires one strip of tape. Versus two in manual carton sealing)

- Easy-to-use without labor fatigue or risk of repetitive-movement injuries

- Durability

- Versatility

There are two common carton sealers for the produce packaging industry: Semi-automatic and automatic.

What Are Semi-Automatic Carton Sealers and How Do They Work?

Semi-automatic carton sealers are an efficient way to package produce, like potatoes and onions. These machines can be used to automatically seal the cartons and then apply labels. Carton sealing machines are also known as carton box sealers or carton closing machines.

Semi-automatic carton sealers work by placing the product into a preformed cardboard box or plastic tray, which is then sealed and labeled with a printer. The machine will typically have two conveyor belts that move the boxes from various stations along the machine. At each station, the operator places new boxes onto one conveyor belt and removes finished ones from another belt. The process continues until all boxes have been processed through the machine.

Semi-automatic carton sealers are often used in grocery stores, warehouses, distribution centers and other businesses that handle large amounts of packaged goods. They help you save time by automating this process so that you don’t have to manually close each box by hand.

What are Fully Automatic Carton Sealers, and How Do They Work?

Fully Automatic Carton Sealers are a food packaging solution that is becoming increasingly popular. They are used to seal cartons of produce items like potatoes, onions, carrots, and other vegetables quickly and efficiently. The fully automatic carton sealers use heat to seal the cartons closed. They are made up of a heated blade that cuts through the top layer of the lid and seals it with a hot glue gun.

The main advantage of using Fully Automatic Carton Sealers is that they can be used to package produce very quickly, which allows you to save time and money. It also reduces the chance of human error and ensures that everything is packaged properly, so there are no leaks or spills.

Recommended Brands and Features of Semi-Automatic and Fully Automatic Carton Sealers

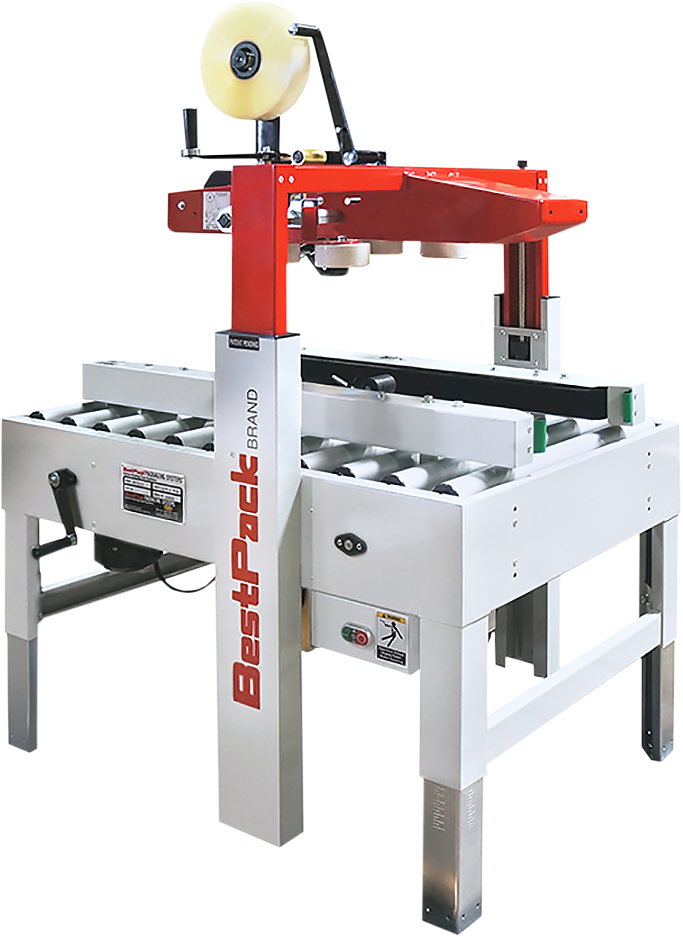

About The BestPack™ Semi-Automatic Carton Sealer

The is a popular adjustable sealer, because it is designed for a variety of light-to-heavy duty applications. Its side belt technology seals narrow to wide cartons, with dual telescopic masts granting an extra 4″ carton height.

Features of the BestPack™ Semi-Automatic Carton Sealer

- 342-490 lbs. shipping weight

- Electrical On/Off box

- Exclusive pressure-pressure sensitive, high-speed tape head

- Side belt drive system

- Telescopic mast

- Extra 4” height adjustment

- Adjustable bed height

- Width/height adjustment knobs

- Upper side compression unit

- A variety of tape roll lengths

- Heavy duty frame

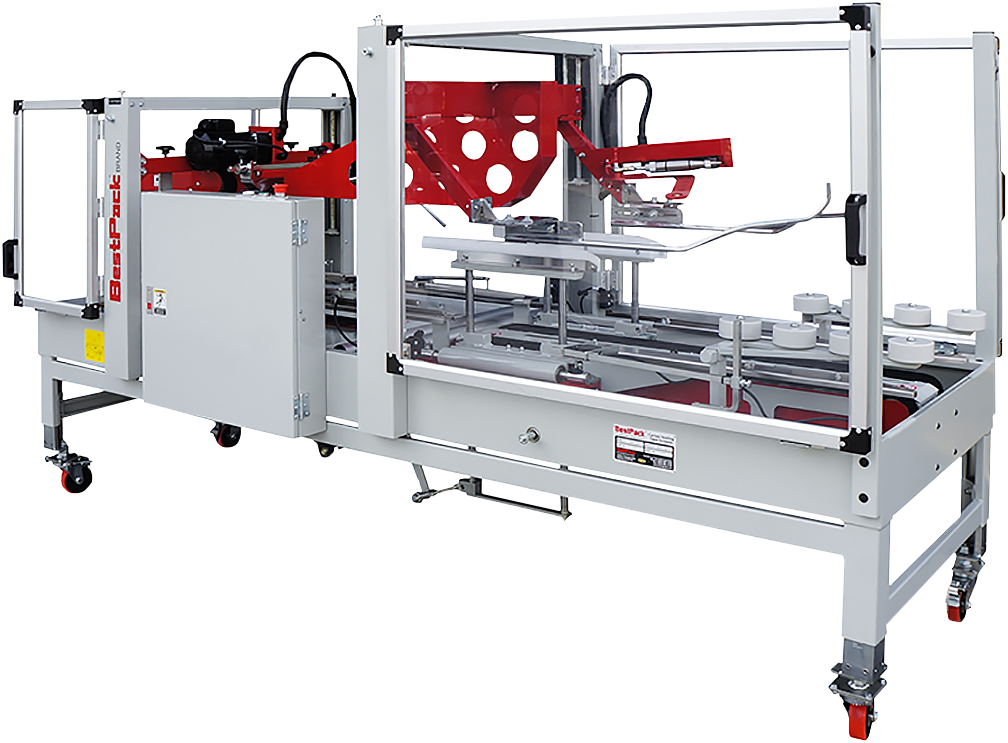

About The BestPack™ ATFXU Fully Automatic Carton Sealer

Designed primarily to seal cartons of produce like potatoes, lemons and oranges, the is designed to be used for heavy duty HSC cartons. It is made with pressure sensitive tape and has four stations:

- Indexer station

- Positive outer sleeve lifting station

- Flap folding station

- Sealer station

Features of the BestPack™ ATFXU Fully Automatic Carton Sealer

- 90 PSI, 8 SCFM air requirements

- 1,098 lbs Shipping Weight

- Heavy Duty Casters Heavy Duty Frame

- Unique Positive Outer Sleeve Lifting Station

- Flap Folding Horns

- Rear Minor Flap Side Action Kicker

- SMC Maitenance Free

- High Speed Top and Bottom Belt Drive System

- Quick Change Belt Drive Assembly Tracks

- Belt Drives are Equipped with a “V” Guide

- Self Centuring Guide Rails

- Width/Height Adjustment

- Adjustable Compression Roller

- Interlock Safety Gates

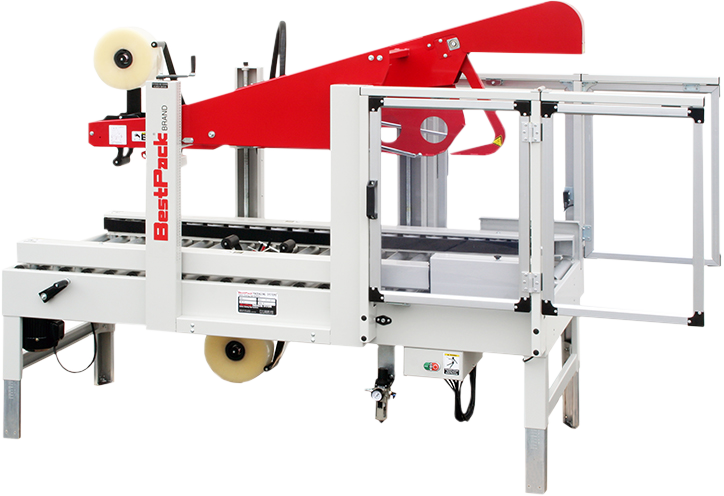

About The BestPack™ AS22-3 Fully Automatic Carton Sealer

The is designed for uniform in-line closures. It has a solid four-column support structure, dual motor side belt, and closes all four flaps on the top of the carton. It uses 45-60psi and 4-5 SCFM of air.

Features of the BestPack™AS22-3 Fully Automatic Carton Sealer

- Various tape roll lengths

- Adjustable bed height

- Width/height adjustment knobs

- Upper side compression unit

- Heavy duty frame

- Interlock safety gates in kicker station

- Electrical On/Off box

- UL-approved electrical parts

- Exclusive pop-out pressure sensitive “High Speed” tape head

Semi-automatic carton sealer vs. Fully automatic carton sealer: Questions to consider

When it comes to choosing a carton sealer, there are many options out there and it can be difficult to know where to start. But one thing's for sure: you need a way to package your produce in a way that keeps it fresh, safe, and appealing to consumers.

So how do you decide which type of carton sealer is right for your warehouse? Here are two questions that can guide your choice depending on your answers:

How much room do you have?

If you're in a smaller space and don't have any extra room for storage, then a semi-automatic carton sealer is probably your best bet. These machines are fairly inexpensive so if something breaks or needs repairs, it won't set you back too far financially. It also means that it doesn't take up much space on its own so if you're tight on space in general, this might be the best option for you!

How many employees do you have?

A fully automatic machine will require more employees than a semi-automatic machine because these types require more hands-on work

Do you need customization for your facility, but aren’t sure where to start? Pepper Equipment offers a variety of machines and solutions for every sized warehouse and facility within the produce industry.

Conclusion

Proper packaging is what your company needs to compete in the produce business. Numerous machines are available on the market, but only some will be perfect for your needs. The right packaging machine helps you maximize your packaging capabilities and save: time, money, labor force and space.

Explore all of Pepper Equipment’s produce industry , and