Potato Vision: AI Image Processing for Potato Grading

The agricultural industry has always been a vital food production and sustenance sector, playing a significant role in the global economy.

Crop inspection is a critical aspect of agriculture that involves evaluating the quality of crops and that could affect their market value or pose health risks.

However, traditional methods of crop inspection are often time-consuming, labor-intensive, and subject to human error.

Artificial intelligence-powered image processing systems specifically designed for potato grading are what we are referring to here as potato vision. It utilizes computer vision and deep learning algorithms to automatically detect and classify defects in potatoes, helping farmers and agricultural companies assess the quality and value of their crops. Potato vision is capable of accurately detecting and differentiating between various types of defects, such as bruises, sprouts, and knots, as well as visualizing these defects in real-time. In addition, it is able to accurately measure the size and shape of potatoes, allowing users to make more informed decisions. Potato vision is a powerful technology that can revolutionize the way potatoes are inspected, graded, and marketed, helping to ensure food safety and quality while streamlining agricultural processes using artificial intelligence and computer vision.

By, we can overcome the limitations of manual inspection and improve the quality of potato crops.

The application of AI in potato defect detection will enable farmers and food producers to identify and manage crop diseases and defects, leading to a more sustainable, efficient, and profitable agriculture industry.

Limitations of Manual Crop Evaluation

Crop inspection is a critical aspect of the agricultural industry that helps identify defects, diseases, and other quality issues that can affect yield and profitability. However, manual crop inspection presents several challenges that can impact the bottom line of businesses in the agriculture industry.

- Subjectivity: Manual inspection involves human perception, which can be subjective and prone to errors. What one inspector might consider a defect, another might not, leading to inconsistent evaluations.

- Inconsistency: Manual inspection also lacks consistency, as different inspectors may apply different standards or methods of evaluation, leading to variations in results.

- Limited scope: Manual inspection can only cover a limited area or sample size, making it difficult to identify defects that are not immediately visible or located in other parts of the crop.

These challenges can significantly impact the bottom line of businesses in the agriculture industry, as they can lead to:

- Reduced yield: Defects and diseases that go undetected can spread and cause a reduction in yield, leading to lower profits.

- Lower market value: Defective crops may not meet market standards and can be rejected, leading to lower prices and financial losses.

- Increased labor costs: Manual inspection requires a considerable workforce and can be time-consuming, leading to increased labor costs that can impact profitability.

While manual inspection has been the traditional approach to crop inspection, it presents several challenges that can negatively impact the 's bottom line.

Therefore, it is crucial to explore alternative approaches, such as AI-powered image processing and computer vision, to overcome these challenges and improve crop inspection accuracy and efficiency.

READ:

AI Image Processing for Crop Inspection

is a technique that uses computer algorithms to analyze digital images and extract information from them.

In agriculture, AI image processing is particularly useful in crop inspection, where it can identify defects, diseases, and other quality issues with high accuracy and efficiency.

How it works:

- Image acquisition: Images of crops are captured using various devices, such as drones, cameras, or smartphones.

- Image processing: process the images, identifying and analyzing the features of the crops.

- Defect detection: The algorithms compare the features of the crops with a pre-trained database of healthy crops, identifying any anomalies that may indicate defects, diseases, or other quality issues.

- Reporting: The analysis results are reported to the farmer or inspector, who can take appropriate action, such as isolating affected crops or applying treatments.

Benefits of AI-powered inspection:

- Reduced labor costs: AI image processing can analyze thousands of images in minutes, reducing the need for manual labor and saving time and money.

- Improved product quality: AI-powered inspection can identify defects and diseases that may go undetected in manual inspections, leading to higher-quality crops and increased market value.

- Increased yield: Early can prevent their spread, leading to higher crop yields and improved profitability.

- Sustainability: AI-powered inspection can help reduce the use of pesticides and other harmful chemicals, leading to a more sustainable agriculture industry.

AI image processing has enormous potential to revolutionize crop inspection in agriculture, improving accuracy, efficiency, and sustainability.

By adopting AI-powered inspection techniques, farmers and food producers can overcome the challenges of manual inspection and ensure the quality and profitability of their crops.

6 Considerations to make before implementing Potato Vision

Potato sorting equipment requires efficient and accurate quality control measures. Implementing AI image processing technology can help streamline the process and minimize errors, but it requires careful planning and execution.

Here are some practical steps and considerations for warehouse managers and produce processing warehouses looking to integrate AI image processing into their potato processing line.

1.) Assess Your Current System

Before implementing AI image processing, assessing your current system and identifying areas that can benefit from automation and improvement is important.

This includes evaluating:

- Current grading, sorting, and packaging processes.

- Inefficiencies or bottlenecks in the processes.

- Possible areas where manual labor can be replaced with automation.

2.) Consult a Project Manager/Supplier

When implementing AI image processing in your potato processing line, it's important to consult with a with experience in the field.

A project manager/supplier can help you identify the specific areas of your potato processing operation that can benefit from AI image processing and recommend the best solution to meet your needs. They can also assist with installation, integrating existing technology, and staff training, ensuring a smooth and efficient transition to the new system.

Investing with a supplier who can provide and can save time and money in the long run and ensure that your potato processing operation remains competitive and profitable.

Streamline your warehouse production line with AI image processing. for expert support, education, and customized solutions.

3.) Determine how you will capture images for AI

AI image processing can be integrated with a wide range of advanced image capturing technologies, such as hyperspectral cameras and X-ray vision cameras.

Choosing a solution that meets your needs and integrates seamlessly with your existing technology and machinery is important.

For example, the integrates x-ray cameras with the as part of a complete ai potato grading system.

4.) Integrate with Existing Technology

Integrating AI image processing with an AI grading system can be a complex process that requires careful consideration of your existing technology and machinery. When choosing an AI image processing solution, it's important to look for options that can be easily integrated with your current systems. For instance, solutions with Ethernet or USB connectivity can facilitate integration with your existing equipment.

To ensure compatibility with your current equipment, it's recommended to consult with the manufacturer or supplier of the AI image processing system. They can provide expert guidance on which solutions will work best with your current technology and machinery, and help you avoid compatibility issues that could cause delays or disruptions to your potato processing line.

5.) Train Your Staff

Integrating AI image processing into your potato processing line requires new skills and knowledge.

It's important to train your staff on operating and maintaining the new system and interpreting and acting on the data generated by AI image processing technology.

WATCH:

To minimize system damage and maximize efficiencies, it's crucial to train your staff in the following key areas:

- Software maintenance

- Hardware maintenance

- Troubleshooting support to quickly resolve any issues that arise with your software or hardware systems.

- Data analysis to help you make informed decisions and optimize your systems for peak performance.

6.) Monitor and Evaluate Performance

The main advantage of AI image processing is its ability to automate tasks and improve efficiency.

However, to fully realize these benefits, analyzing the system's data, monitoring and evaluating its performance, and using that information to address issues or improve quality are crucial.

Following these practical steps and best practices, you can successfully implement AI image processing in your potato processing line and take your operation to the next level.

AI Imaging in Potato Processing: Overcoming Technical and Data-related Challenges

As , more and more potato processing warehouses are integrating AI image processing systems into their production lines to improve efficiency, accuracy, and quality. However, with any new technology comes challenges, both technical and data-related.

There are practical steps that warehouse managers can take to ensure the smooth integration of AI image processing into their potato processing lines, which includes selecting the appropriate equipment and software and managing and analyzing the data generated by the system.

With meticulous planning and attention to detail, potato processing warehouses can fully maximize the potential of AI image processing technology and maintain a competitive edge in the industry.

AI image processing for crop inspection has it's challenges

- Data privacy concerns:

Collecting and processing images of crops can raise privacy concerns, particularly if the images contain sensitive information, such as GPS coordinates or other identifying features.

- Specialized expertise:

Developing and implementing an AI image processing system requires specialized expertise in areas such as computer vision, data science, and software engineering.

- Potential biases:

The training data used to develop the AI model may contain biases that could affect the accuracy of the system. For example, if the dataset only contains images of crops grown in a specific region or climate, the model may not be accurate when applied to crops grown in other regions.

To address these challenges, it's essential to take a strategic approach to implementation, including:

- Ensuring data privacy: Adopting data privacy policies and practices to protect the confidentiality of the data collected.

- Building a multidisciplinary team:

Assembling a team with expertise in different areas, such as agriculture, computer science, and data analysis, to ensure the success of the implementation.

- Addressing biases in the training data:

Using diverse datasets that represent a broad range of crops, regions, and growing conditions, and regularly monitoring the system's performance to identify and correct biases.

Examples of Real-world Advantages of AI Implementation in Agriculture

The integration of Artificial Intelligence (AI) in agriculture has transformed the sector by enhancing efficiency, productivity, and sustainability.

- According to research by BI Intelligence, the global revenue for smart, connected agricultural technologies and systems, which includes AI and machine learning, is expected to triple by 2025, reaching $15.3 billion. (Source: )

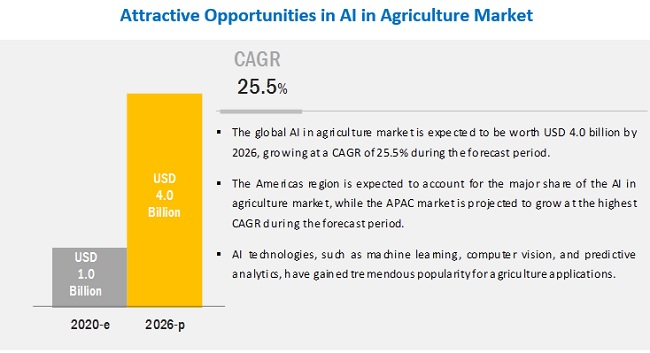

- Markets&Markets predicts that spending on AI technologies and solutions in agriculture will increase from $1 billion in 2020 to $4 billion in 2026, with a Compound Annual Growth Rate (CAGR) of 25.5%.* The CAGR is expected reach a value of .

- The fastest-growing technology segment in smart, connected agriculture is monitoring, which is expected to reach $4.5 billion by 2025.*

The bottom line

Implementing AI image processing for crop inspection can revolutionize the agriculture industry by replacing traditional manual inspection methods with more accurate, efficient, and cost-effective solutions.

Although there are challenges in implementing AI image processing, such as data privacy concerns, the need for specialized expertise, and potential biases in the training data, these challenges can be addressed with careful planning and a strategic approach.

As businesses in the agriculture industry seek to improve their product quality, increase their yield, and reduce labor costs, AI-powered crop inspection presents a promising opportunity. By leveraging the benefits of AI technology, such as machine learning and computer vision, businesses can unlock new insights and efficiencies that were previously impossible.

To remain competitive, profitable, and scalable, businesses need to consider the adoption of AI-powered crop inspection.

Contact Pepper Equipment Co. Today for AI-Powered Solutions

Don't wait any longer to revolutionize your agricultural business with our cutting-edge AI solutions. today and let us help you take your operations to the next level!