Are You Choosing The Right Size Potato? Our Quick Guide and Potato Sizing Equipment Can Help!

The potato is one of the most versatile vegetables on the market today. It is used in a variety of food products— both straight to consumers or for commercial use. It’s even used in and other eco-friendly products!

Because the potato is one of the highest-demand crops, your warehouse must deliver a quality product quickly and efficiently and address the challenges of grading and sizing different groups of potatoes.

Integrating the proper technology and machinery can produce consistent grading and sizing of potatoes eliminating error, waste, and extra time when done manually increasing your warehouse output, bottom line, and getting your product out to consumers faster than ever.

But first, let’s cover how potatoes are graded and sized to standard.

How are Potato Grading Standards Different from Potato Sizing Standards?

Potato Grading Standards

After harvest, all U.S. potatoes are inspected and sorted for quality and consistency according to the . The United States Department of Agriculture (USDA) created the grading system in 1912 to increase efficiency and quality and decrease waste by offering sizes and standards for commercial use, restaurants, and those you find in grocery stores for purchase and consumption.

The current USDA grading system consists of three main classes:

- U.S. No. 1

- U.S. No. 2

- U.S. Commercial

The classes are based on specific characteristics: size, shape, surface defects (such as bruising or chips), internal defects (such as hollow heart), decay (internal browning), and coloration (including color uniformity.)

Potato Sizing Standards

While potatoes are graded according to look and feel, they are also categorized by size and weight. Potatoes are sized and categorized into three main classifications:

- Size A potatoes (large):

- Diameter: typically 1.75 - 2.5 inches

- Weight: more than 10 ounces

- Varietals: Russet potatoes and some types of sweet potatoes

- Size B potatoes (medium):

- Diameter: typically 1.5 -2.25 inches

- Weight: between 5 - 10 ounces

- Varietals: Larger white, red, and purple potatoes

- Size C potatoes :

- Diameter: typically less than 1.5 inches in diameter

- Weight: between 5 - 10 ounces

- Varietals: a small variety of white, red, purple, and fingerling potatoes

There are also sizing charts for smaller potatoes, but sizes A, B, and C are the most common.

Other sizes are:

- Size D potatoes: 1.25 - 1.5 inches in diameter

- Size E potatoes: 1 inch in diameter

- Size F potatoes: .75 -1 inch in diameter

- Size G potatoes: .5 - .75 inches in diameter

- Size H potatoes: .25 - .5 inches in diameter

Potato Sizes Chart

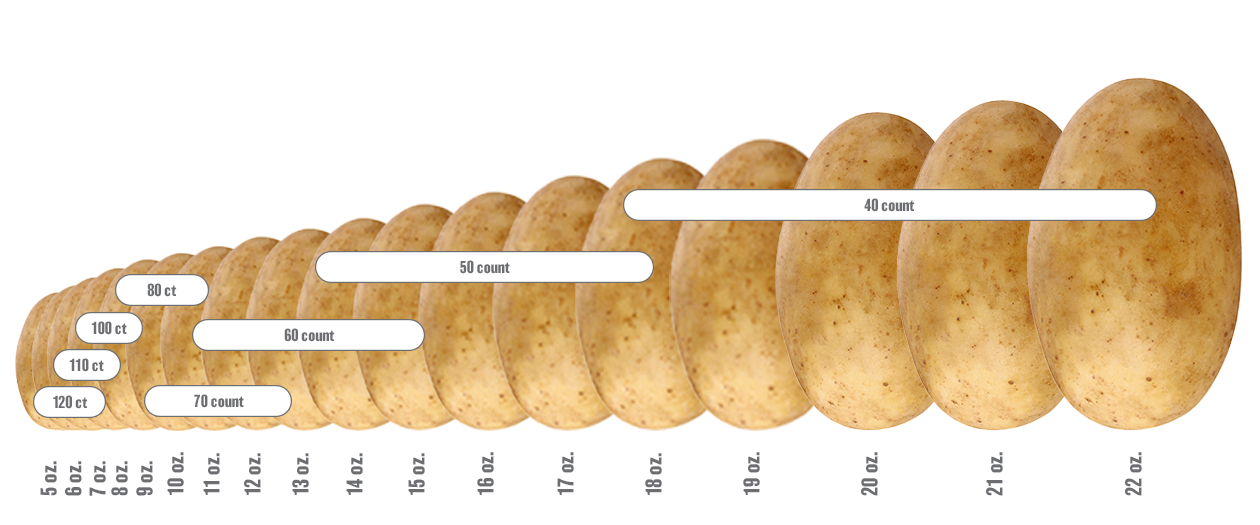

After harvest, potatoes are bagged according to “counts”: how many potatoes will fit in a 50-pound carton during the bagging, packaging, and fulfillment process at the end of the warehouse’s production line.

For example, the common count for the most common potato harvested is the 70 count Russet.

For visual reference, here is an example from of the different sizes of one of the most common and popular U.S. potatoes, the Russet:

Image credit:

What is a Potato Sorter?

The produce processing industry follows USDA standards for grading and sizing potatoes and other root vegetables and onions

After harvest, the potatoes arrive at the production line, where they are sorted, washed, weighed, and bagged according to standard.

The production line for potatoes has grown more efficient and accurate thanks to AI and automation.

Pepper Equipment Co, one of the leading produce machinery and solutions providers in North America, offers a variety of state-of-the-art grading, sizing, weighing, and bagging solutions to ensure every potato on the line meets the USDA grading and sizing requirements like the:

- Features:

- Up to 15 Tonne Pr/Hr

- Stainless Steel Smooth Rollers

- Quick Adjustment Levers

- Simple Chain & Roller Design

- Benefits: This two-point contact sizer is ideal for oblong produce like sweet potatoes, carrots, and elongated potatoes

See the edp Lift Roller Sizer in action:

: This machine is the best-in-class artificial intelligence and machine learning solution for grading potatoes.

- Features:

- Integrates with your current warehouse system

- Benefits:

- Reduces up to 60 percent of sorting labor costs

- Consistent potato sorting

- Reliable potato grading

- Average of 98.5 percent cull line accuracy

- Increased throughput

See the Bantam Vision Grading System in action:

Watch this video of a Pepper Equipment production line in action. Although the produce being processed here are onions, Pepper Equipment’s production line machinery and technology also apply to potatoes and other root vegetables:

What are the grades and sizes of the potatoes found at a grocery store?

Out of all the different grades and sizes mentioned above, to give you some perspective, typically, the potatoes sold at grocery stores are A, B, or C.

Learn more about the

Using the USDA grading system for potatoes, consumers can feel safe purchasing and eating American potatoes. From a business standpoint, the system enables growers to efficiently track which sizes and types of potatoes will have the highest demand.

Ready to implement Pepper Equipment’s sizing and grading solutions to increase quality and efficiency in your potato sizing and grading process?