USDA Potato Grade Standards and the Grading Equipment You Need to Achieve Them

Gone are the days of harvesting and grading by hand. Now, technology and nature meet to ensure the quality of your potatoes from field to consumer. Today, you're responsible for feeding a nation, so the quality and health of your product is your number 1 priority, but how are you meeting the number 1 priority for the USDA’s potato grading standards?

The are defined by the following criteria to achieve the US. No. 1 status within these categories:

- Cleanliness

- Sizing

- Damage-Free

- Disease-Free

- Shape

- Firmness

From the infeed system to the potato sorting machine, potato cleaning and sizing machines and other grading equipment are essential to achieving quality potato grades.

Potato Cleanliness

Cleaning plays a crucial role in post-harvest potato processing. Getting a quality lot of potatoes means the majority (90 percent) of the lot is free from dirt and staining, including removing dirt and foreign material in packaging and storage.

We recommend a variety of quality to help your product reach the US. No. 1 potato standard for cleanliness during processing and packaging.

Potato Sizing and Shape

Quality assurance for the perfect US No.1 potato is always a priority when processing post-harvest.

In today’s advancing world of technology, ai computer vision companies are leading the way in offering for efficient and consistent sizing and shape selection for potato varieties such as:

- Creamer

- Chef

- Small

- Medium

- Large

- Size B

- Size A2

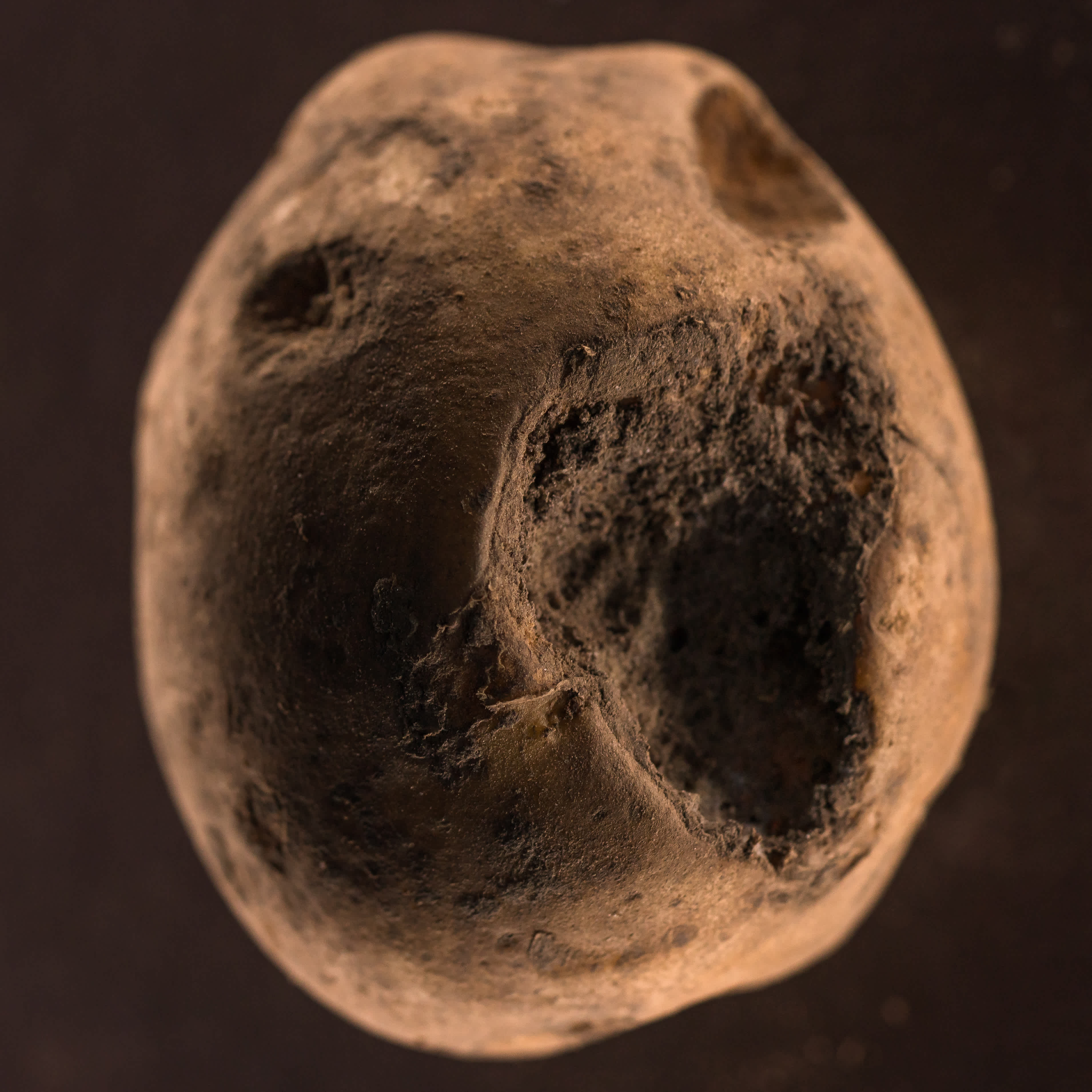

Damage and Disease-free Potatoes

Working with nature, defects, and disease is a part of agriculture. That goes for potatoes too, but the diseased and damaged product won't make the cut with proper monitoring post-harvest, ensuring that only the potatoes that meet the highest standards are bagged and shipped.

Advanced technology and machinery monitor and separate defective, misshapen potatoes before they reach the market effectively and precisely.

Potato Firmness = Disease-Free

In addition to shape, size, and weight, US No. 1 potatoes are graded by firmness and the absence of internal or external disease and discoloration.

When it comes to potatoes, ‘firmness’ addresses the flesh and skin of the potato. Damaged or diseased potatoes are usually shriveled or soft, indicating potential internal defects or disease. But if the condition is internal, how do you know for sure without cutting into the potato? Of course, it’s not efficient or realistic to cut open every potentially defective potato in the lot, so what’s a better solution?

Use artificial intelligence and in your post-harvest production line. With this technology, most diseases and defects like hollow-heart and black heart, blight, wilt, ring rot, and soft rot can be detected and separated from the lot before reaching your consumer.

No matter how big or small your processing warehouse is or where your product ends up, having the technology you can count on to help you achieve the best grades of potatoes while saving you time and money. Suppose these defective potatoes make it past production and onto the truck? Your product value and reputation decrease, and so do your bottom line. Start with early detection and only present your highest quality potatoes to your consumers.

Are you looking for produce solutions? , your solution for producing industry solutions.