Why Consumer Baggers are key to End-of-Line Packaging in Agriculture

Collecting, sorting, and packaging potatoes and other crops can be time-consuming, labor-intensive, and often expensive for farmers.

That's where end-of-line packaging and consumer bagger equipment comes in. In this blog post, we will explore the benefits of using consumer baggers for potatoes, onions, and other root vegetables.

From increased efficiency to improved product quality, we will show how consumer baggers can help farmers streamline their post-harvest processes and improve their bottom line.

The Evolution of End-of-Line Agricultural Equipment

The history of agricultural bagging machinery is a fascinating one. From the early days of manual labor to the advanced machinery today, the agricultural industry has come a long way in post-harvest production.

Photo credit: - Pre-agricultural revolution farmhand manually harvesting and bagging potatoes in Idaho.

Before the advent of modern agricultural machinery, farmers had to rely on manual labor to collect, sort, and package their crops; this was a time-consuming and labor-intensive task that often required a large workforce.

As the demand for agricultural products grew, farmers began to search for more efficient ways to handle their crops.

The first mechanical bagging machines were invented in the late 19th century.

These machines used a series of gears and pulleys to automate the bagging process. However, these early machines were limited in their capacity and were prone to breaking down.

Illustration of 19th century potato bagger.

It was in the 1930s that the first fully automated consumer bagging machines were designed.

These machines used conveyor belts to transport the crops and automatic stitching machines to close the bags marking a significant improvement in efficiency and productivity.

In the following decades, bagging machines continued to evolve.

Advances in technology led to the development of computerized bagging machines, which could automatically weigh, sort, and bag crops. These machines also allowed farmers to customize the size and shape of their bags, making it easier to package crops for specific markets.

Today, agricultural bagging machinery has become an essential part of post-harvest production. From small-scale farms to large commercial operations, farmers rely on bagging machines to streamline their processes and increase their efficiency.

As technology continues to advance, we can expect to see even more innovations in agricultural bagging machinery in the years to come.

Learn about the history of the potato sorter

Benefits of Using Consumer Bagger Equipment

Using consumer bagger equipment for agriculture offers several benefits, including:

- Increased Productivity

- Bagger equipment helps farmers to bag their crops more quickly, saving time and increasing productivity. It can pack crops into bags at a rate of up to 12 bags per minute, making it an efficient option for mid-to-large-scale farmers.

- Improved Crop Quality

- Bagging crops with consumer bagger equipment creates an air-tight seal that helps preserve the crop's quality. The air-tight seal keeps moisture out and prevents the growth of bacteria and fungi, which can reduce the quality of the harvest and lead to spoilage.

- Reduced Labor Costs

- Bagging crops with consumer bagger equipment reduces the need for manual labor, which can be expensive. It can be operated by a single person, freeing up other workers to perform different tasks on the farm.

- Increased Profitability

- By preserving the quality of the crop, farmers can sell their bagged products for a higher price. Additionally, using consumer bagger equipment can help to reduce waste and improve inventory management, leading to increased profits.

4 Things to Consider Before Installing End-of-Line Packaging Equipment

When researching and purchasing end-of-line consumer bagger equipment for agriculture, there are several factors to consider, including:

1. Facility Size:

The size of your facility will determine the size and capacity of the bagger equipment needed. Larger packaging facilities may require more powerful equipment to meet the demands.

2. Facility Layout:

The facility layout will also influence the type of equipment required. For instance, warehouses with uneven surfaces may necessitate equipment with larger tires for improved maneuverability.

Customize your facility with Pepper Equipment, Co.. Experience technology, innovation, and exceptional service to create the perfect solution. See what we can do for you .

3. Crop Type:

Different crops may require different types of bagger equipment. For example, crops with high moisture content may require equipment with a larger hopper to prevent clogging.

4. Warranty and Support:

Choosing a manufacturer and supplier that offers warranty and support services is vital. Doing so ensures swift resolution of equipment issues, minimizes downtime, and reduces the likelihood of crop loss.

By considering these factors, farmers can make an informed decision when choosing consumer bagger equipment for their farm.

Curious about edp baggers?

Exploring the Diverse Range of Consumer Baggers: Features and Functions

Different bagging machines cater to varying needs and come equipped with unique features.

Here are the common types of consumer baggers, their specific functionalities, and the benefits they offer:

- Vertical Form, Fill, and Seal Bagger

Vertical form, fill, and seal baggers, like the , are versatile and widely used packaging solutions.

Vertical form, fill, and seal baggers, like the , are versatile and widely used packaging solutions.

This consumer bagger efficiently forms bags from a roll of film, fills them with the desired product, seals them, and handles various bag sizes and materials, including pillow bags and gusseted bags.

The efficiently forms bags from a roll of film, fills them with the desired product, seals them, and handles various bag sizes and materials, including pillow bags and gusseted bags.

This type of consumer bagger ensures versatility, reliable performance, efficient packaging, minimized material waste, and enhanced product protection.

See the JASA 350 Intermittent Vertical Form, Fill, and Seal Bagger in action

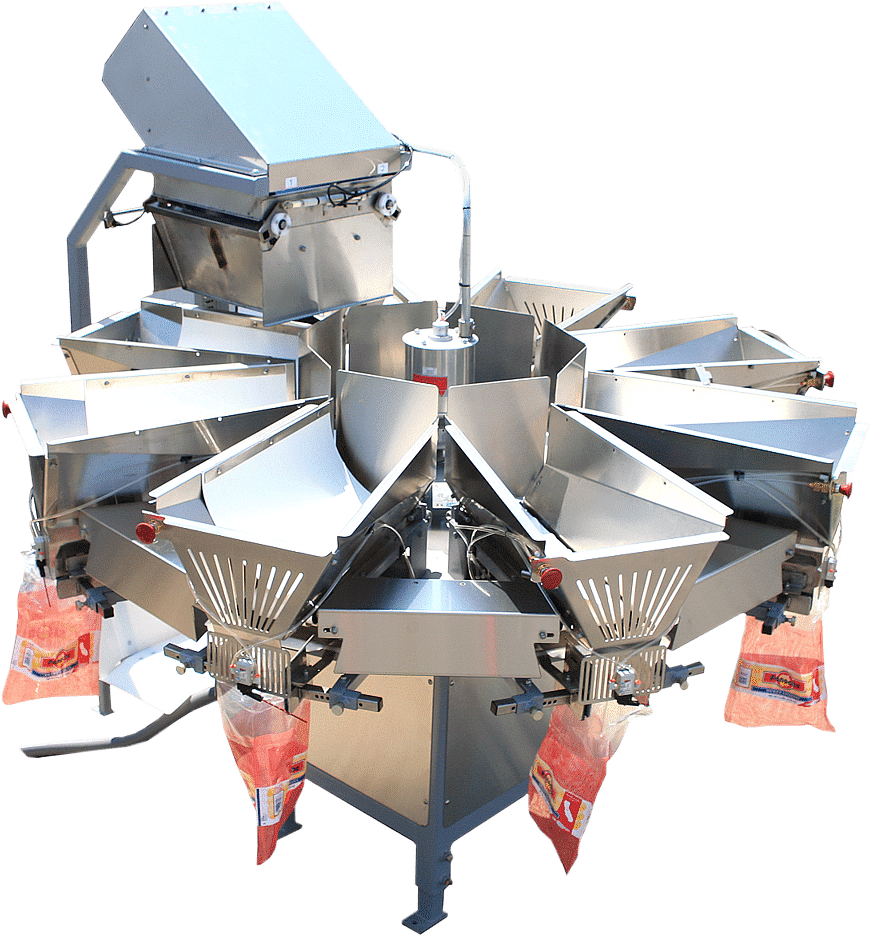

- Semi-Automatic Carousel Bagger

Semi-automatic carousel baggers combine the convenience of manual loading with automated bagging. A popular choice for consumer semi-automatic carousel baggers is the AGPAK Octo-Pak.

Semi-automatic carousel baggers combine the convenience of manual loading with automated bagging | AGPAK Octo-Pak | Pepper Equipment, Co.

This machine utilizes a rotating carousel that brings the bags to each station.

The operator manually fills the bags while the machine handles the sealing process. It is ideal for small to medium-scale operations, balancing productivity and affordability.

Typically, the Octo-Pak is placed alongside a weigher to handle miscellaneous bag types, while a high-volume bagger like Ag-Pak's AP7000 operates simultaneously on the other side.

See the AGPAK Octo-Pak Semi-Automatic Carousel Bagger in action

- Automatic Net Packaging Machine

The C-Pack VAC 929 Automatic Net Packaging Machine is an exemplary example of a fully-automatic net packing machine designed for various fruits and vegetables, including potatoes, onions, citrus fruits, and other solid products.

C-Pack VAC 929 Automatic Net Packaging Machine is an exemplary example of a fully-automatic net packing machine.

Tailored for produce such as onions, potatoes, and citrus fruits, that necessitate breathable packaging, these machines employ netting material to securely enclose the items.

Potatoes, onions, and oranges are prime examples of produce that greatly benefit from net bagging machines.

This design allows for air circulation, , extending shelf life, maintaining optimal freshness, and streamlining the packaging process.

See the C-Pack VAC 929 Automatic Net Packaging Machine in action

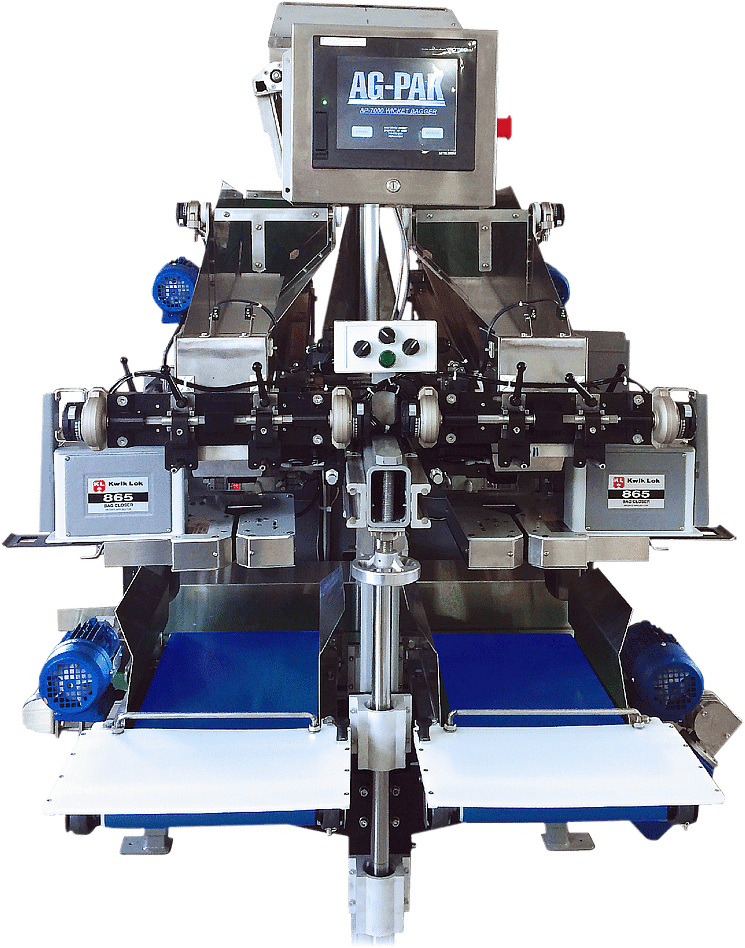

- Wicket Bagger

Wicket baggers, like the , are a popular choice due to their speed, reliability, ease of operation, and maintenance. This bagger features twin bagger heads fed from two collectors, enabling higher packaging efficiency.

Wicket baggers, like the , are a popular choice due to their speed, reliability, ease of operation, and maintenance. | Pepper Equipment, Co.

The filled polypropylene or mesh bags are sealed using standard, ensuring secure and convenient closure. Wicket baggers are highly efficient for industries that require high-volume packaging with consistent quality.

(bottom) Example of wicketed polypropylene produce bags. (top) Example of wicketed mesh bags.

By understanding their unique features and functions, businesses can make informed decisions to optimize their packaging processes and enhance customer satisfaction.

See the Ag-Pak AP700 Wicket Bagger in Action

THE BOTTOM LINE

In conclusion, the evolution of consumer bagging equipment has revolutionized the packaging process for potatoes, onions, root vegetables, and citrus fruits. From humble beginnings to advanced machinery, these baggers have greatly enhanced productivity, efficiency, and product quality in the produce industry.

The benefits and features of modern consumer bagging equipment are remarkable. These machines ensure consistent bagging results, minimize product damage, and maximize shelf life. From the versatility of vertical form, fill, and seal baggers to the convenience of wicket baggers, businesses can choose the right equipment to meet their specific needs.

Investing in high-quality bagging equipment customized for your harvest and warehouse needs can streamline their packaging processes, improve product quality, and ultimately achieve success in an increasingly competitive market.

Take the next step towards optimized packaging

Unlock the potential of your produce packaging with Pepper Equipment Co., trusted by customers across over 40 states, Canada, and Mexico. In the heart of the San Luis Valley (the second-largest fresh potato growing region in the U.S.), Pepper Equipment Co. understands the industry's unique needs.

Contact them today at to explore the transformative capabilities of their top-of-the-line produce equipment.

Take the next step towards optimized packaging by contacting today!

ABOUT US

Pepper Equipment Co. is a reliable and reputable supplier of top-of-the-industry produce equipment. With a wide range of cutting-edge bagging solutions, they offer innovative technologies tailored to the produce industry's unique requirements.

Pepper Equipment Co. provides state-of-the-art equipment that guarantees exceptional packaging results, whether it's potatoes, onions, root vegetables, or citrus fruits.